Technology is impacting every industry, and insulation accessories are no exception. Now, manufacturers are turning to smart factories to streamline the production of various insulation accessories, such as insulation blankets and thermal covers. These smart factories leverage smart technology solutions to enhance the quality of production and reduce waste.

Read on to learn more about how the insulation accessories industry is entering an era of smart manufacturing!

Smart Manufacturing: What Is It?

1. Definition

Smart manufacturing is driven by technology that utilizes Internet-connected machinery to monitor and enhance the production process. It is a subset of Industry 4.0, which refers to the ongoing transformation in industries and manufacturing through the integration of digital-physical technologies.

Smart manufacturing aims to optimize the manufacturing process by leveraging technologies such as the Internet of Things, powerful big data computing capability, machine learning, and automation. With all these elements, the whole manufacturing industry owns “the ability to solve existing and future problems through an open infrastructure that allows solutions to be implemented at the speed of business while creating advantaged value.”[1]

2. The Reasons to Become Future

Smart manufacturing is heralded as the future for the entire industry due to its ability to transform traditional manufacturing processes into highly efficient, automated, and data-driven operations.

Improved Efficiency: Smart manufacturing optimizes production through automatic operation, reducing bottlenecks and downtime to enhance productivity.

Cost Savings: Predictive maintenance and resource optimization lower operational costs by preventing expensive failures and reducing waste.

Enhanced Quality: Continuous monitoring with sensors ensures products meet quality standards, reducing errors and increasing customer satisfaction.

Flexibility and Agility: Adaptable manufacturing systems quickly adjust to market changes, allowing for faster response to customer demands and product customization.

Innovation and Competitiveness: Integrating IoT and analytics drives process innovation, helping industries stay competitive by advancing technology use and improving products.

The Current Situation in the Insulation Accessories Industry

Currently, the installation accessories industry is growing but is also grappling with many challenges.

1. The Growing Market

The insulation accessories industry is on a robust growth path, with the global market reaching USD 61.36 billion in 2022 and projected to grow at a steady CAGR of 6.6% moving forward[2]. Particularly vibrant is the thermal insulation market, which stood at USD 28.6 billion in the same year and is poised to climb to USD 35.6 billion by 2029, expanding at an impressive CAGR of 7.2% from 2024 to 2030[3].

These figures highlight a sector that is not only growing but also evolving rapidly to meet increasing global demands. That is one of the reasons that the insulation accessories market is boosting. Besides, the economic expansions in emerging markets such as Asia Pacific and Latin America are playing a pivotal role. As these regions experience rapid infrastructure development, the demand for advanced insulation solutions is surging to meet new construction standards and energy regulations.

Simultaneously, the push for sustainable building practices is intensifying with the global rise in population and urbanization. More people moving to urban areas translates to a higher volume of residential constructions, each requiring modern insulation solutions to meet stringent energy efficiency standards.

These factors contribute significantly to the dynamic growth observed in the insulation accessories market, underlining the industry’s adaptability and its critical role in the global push towards more sustainable and energy-efficient construction practices.

2. The Facing Challenges

Despite the insulation industry’s robust growth and expanding market reach, it faces several significant challenges that could impact its future trajectory. Taking specifically, here is how:

Limited Efficiency: Most of the insulation accessories industry is struggling with inefficient production processes. Traditional methods involve plenty of manual work, which is not only slow but also prone to errors. This inefficiency leads to higher costs and longer production times.

Sustainability Concerns: The outdated methods of manufacturing insulation accessories result in a lot of waste and require maximum energy, which isn’t good for the environment. That’s why there is also a growing need for eco-friendly practices in the insulation accessories industry.

Compliance Challenges: The insulation accessories industry has to adhere to various regulations and standards to guarantee the safety and quality of final products. However, these regulations often change frequently, and keeping up with them can be challenging, resulting in hefty fines and reputational damage.

Lack of Monitoring: Most manufacturers also lack the ability to monitor their production processes in real time. This makes it difficult to pinpoint issues timely, leading to low-quality products and increased wastage.

4 Aspects that Smart Manufacturing Impacts Insulation Accessories Manufacturing

As mentioned earlier, smart manufacturing comprises various vital elements like IoT, machine learning (ML), Digital Twins, Cloud Computing, and Robotics. Here’s an overview of how smart manufacturing impacts insulation accessories manufacturing:

Predictive Maintenance

IoT and ML help predict when your manufacturing equipment might fail or need maintenance. This predictive maintenance prevents unexpected downtime and saves around 8% to 12% over preventive maintenance costs[4].

Testing & Monitoring

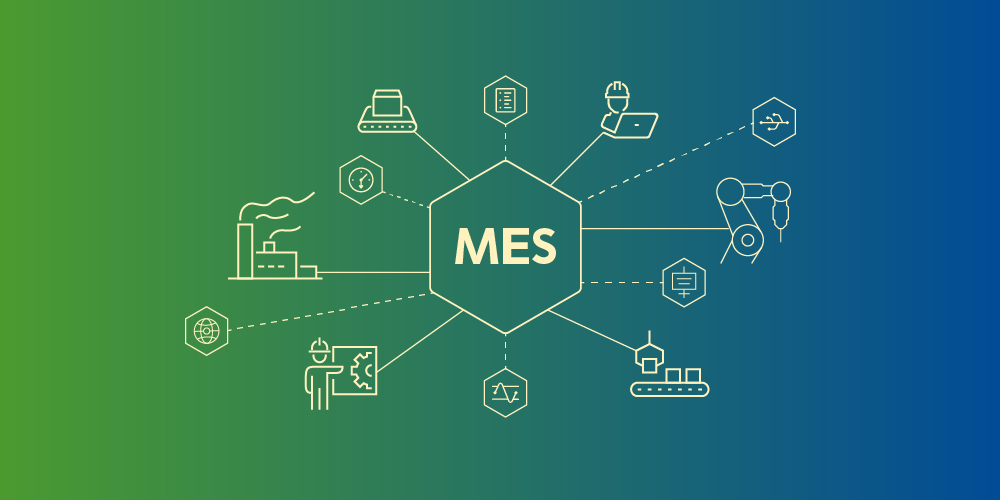

The function of computer-aided manufacturing or smart systems, like the MES, is to simulate insulation accessories production lines, test changes before implementation virtually, and monitor the perfection of each insulation accessory. It gives an overview of how a product will perform under certain conditions and reduce costs associated with expensive remanufacturing.

Automation

Robotics and other automation technologies streamline repetitive tasks to achieve high precision, faster production times, and lower labor costs.

Compliance

Smart manufacturing solutions also make sure that the production processes adhere to specific regulations. The purpose is to stay compliant with mechanical insulation supply chain standards and avoid fines.

3 Technologies That Help Flyaford Manufacture Reliable Insulation Accessories

We, Flyaford, are a manufacturer of insulation accessories that leverages smart manufacturing technologies to enhance its production line. Here’s how these technologies contribute to our reliable insulation accessories to deliver the goal of smart manufacturing:

1. MES

An MES (Manufacturing Execution System) acts as the central nervous system of Flyaford, providing real-time data on production processes and inventory levels. It plays a role in decision-making, allocation optimization, and monitoring, laying a great foundation to achieve smart manufacturing.

2. MEP System

MEP (Mechanical, Electrical, and Plumbing) ensures the whole insulation manufacturing process is in an excellent environment in order to keep the best performance. We also have MEP systems that automate the manufacturing process of insulation products, embodying temperature control in particular. Insulation accessories manufacturing often involves processes that require specific temperature conditions. MEP systems, particularly mechanical systems, such as heating, ventilation, and air conditioning (HVAC), help maintain the desired temperature levels automatically throughout the manufacturing facility in order to create the best smart manufacturing environment.

This ensures that insulation materials are produced under optimal conditions, leading to consistent quality and performance in our Flyaford’s insulation accessories production.

3. Automated Robotic Operation

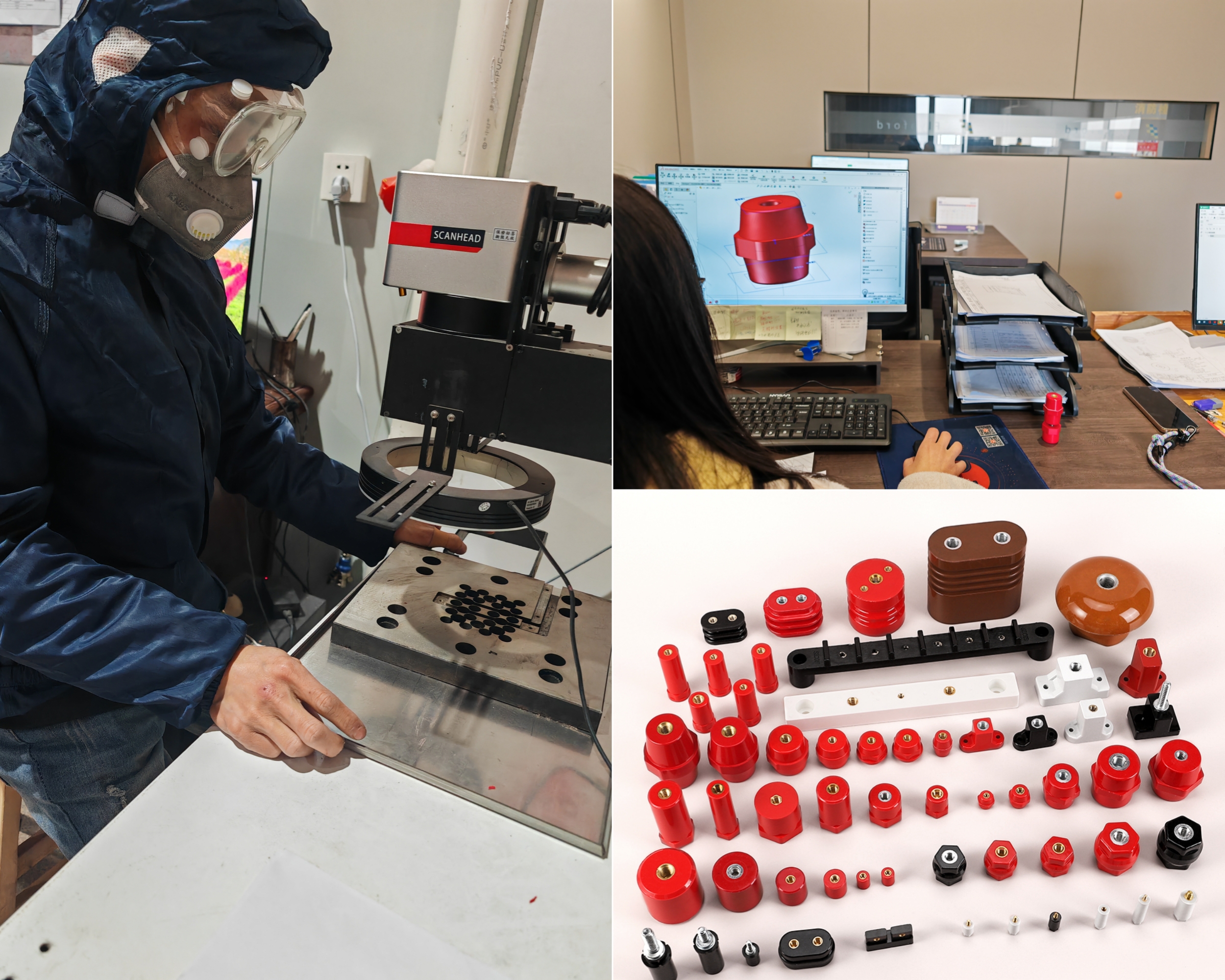

Flyaford also uses robotic automation in its production line for repetitive tasks. That is a sign of smart manufacturing, which fixes conventional issues like material handling and assembly. As a result, we can manufacture with less labor cost so as to make the offer more cost-effective while ensuring an accurate production for your insulation accessories demands.

3 Unique Advantages of Flyaford

Our smart manufacturing technologies can solve the challenges of manufacturing insulation accessories. Besides, our research capabilities in insulation production are also making us one of the best insulation accessories manufacturers in the market.

1. Well-Equipped Testing and Quality Control System in a Professional Lab

At Flyaford, we pride ourselves on our commitment to quality and precision, underscored by our well-equipped testing and quality control system housed within our professional lab. Our facility in the factory is fully compliant with top industry standards, including IATF16949, ISO14001, and ISO9001, ensuring that every product can meet the highest quality benchmarks.

Our lab is outfitted with advanced testing equipment to conduct thorough and accurate assessments. This includes 2D projectors, flash testers, microcomputer-controlled torque testers, high and low-temperature test chambers, dual 85 test boxes, hardness testers, metallographic microscopes, and universal testing machines. Each equipment plays a critical role in our comprehensive quality system, allowing us to maintain and deliver products, meeting but exceeding customer expectations in durability, functionality, and compliance.

2. Patents

For now, we have gained 13 Patents for Utility Models, and we are applying for 2 Patents for Inventions. Flyaford’s dedication to research and development is evident, which covers everything from innovative material formulations to unique insulation products. That’s why we have been recognized as a National High-Tech Enterprise in China.

Conclusion

Smart factories make it easy to develop top-quality, regulatory-compliant insulation accessories. Manufacturers can benefit from efficient production lines and reduced wastage. Wondering which company is best for insulation accessories? Look no further than us, Flyaford! We have an extensive range of insulation products and can even customize them to your needs. If you are interested, please visit our Flyaford’s official website to learn more information and contact us!

Reference

- Available at: https://www.cmtc.com/blog/adopting-smart-manufacturing-technologies?hs_amp=true

- Available at: https://www.grandviewresearch.com/industry-analysis/insulation-market

- Available at: https://www.precisionbusinessinsights.com/market-reports/thermal-insulation-market

- Available at: https://upkeep.com/learning/maintenance-statistics/